ABOUT PLASTIC SCRAP

#1: PETE or PET Most often called PET, #1 bottles are made of polyethylene terephthalate. This plastic is most commonly used for water and soda bottles, peanut butter and other food jars, and such. Only about 20% of these containers are recycled; they can be made into polar fleece, carpet, new containers and more. These are the plastics most commonly picked up by curbside recycling programs.

#2: High Density Polyethylene (HDPE) HDPE is a very versatile plastic that is used in a variety of products. HDPE is used for thin products such as milk jugs and juice bottles, butter and yogurt tubs, cereal box bags, sandwich bags, shopping bags and garbage bags, among other things. #2 plastics are commonly picked up with curbside recycling and can be recycled into new bottles, floor tile, drainage pipe, lumber, fencing and more.

#3: Vinyl or PVCThese bottles are most often used for storing cleaners and detergents, as well as plumbing pipes, but can also be found in some medical products, siding, building windows and more. #3 plastic is rarely recycled, but some facilities will take it to be recycled into siding or lumber products. Heating PVC releases many toxins, thus they cannot be burned and melting must be highly controlled.

#4: Low Density Polyethylene (LDPE)These plastics are usually thin and pliable, and are used for shopping bags, squeezable bottles, frozen food containers, clothing, furniture and more. These plastics are rarely recycled, though more facilities are starting to accept them.

#5: Polypropylene (PP)) Most commonly found in some condiment bottles, as well medicine bottles and straws, PP plastics can be recycled into brushes, battery cables, and a huge variety of materials. However, they have rarely been accepted by most recycling facilities. Recently, though, more curbside recyclers have started to accept them.

#6: Polystyrene (PS)) Most commonly used in foam cups, plates, egg cartons and carry-out containers, PS plastics can be recycled into insulation, among other things, but rarely are. Recent research has suggested that this plastic can leach toxins into food when heated, so some companies are moving away from this product for food containers.

#7: Miscellaneous ) This category basically refers to a variety of plastics (from sunglasses to water bottles) that do not fit into other categories. These are very rarely recycled.

How Can Recycling be More Efficient )

Recycling is a challenging business which requires an expenditure of energy and the use of water. Everyone can make recycling more efficient by helping minimize the required steps to recycling. This includes putting only recyclable material into the recycle bins (checking the number of the item against the allowable recyclables by the company), and removing caps which are made of lesser plastic that can rarely be recycled. While many curb side pick-up companies do not require customers to remove labels or clean the recyclables, doing so does make the job of recycling easier and less expensive, allowing the recycling company to recycle more material and thus be more efficient.

HOW RECYCLING HAPPENS?

Sorting & Washing Materials

The first step is to sort out the different types of recyclable products at a recycling facility. We follow single stream recycling, in which all items are collected at once, so first it’s necessary to separate out basic categories. Next, the plastic needs to be sorted for recycling. Plastic is sorted by types.

Crushing/ Shredding Materials

After sorting, the plastic is ground into chips or flakes. The shredding stage is when the waste plastic is taken and loaded on to conveyor belts or directly in to huge hoppers that funnel the clean scrap towards rotating metal teeth that rip the plastic in to small pellets which are bagged up afterwards ready for testing.

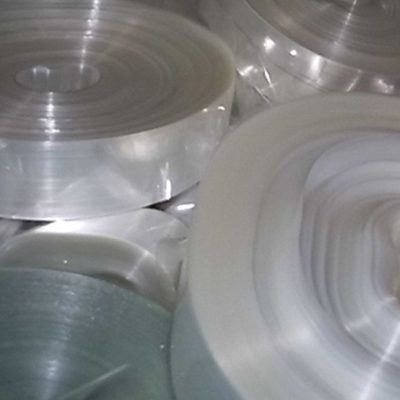

Melting & Extruding Materials

This is the final stage in recycling plastic, this involves melting the clean shredded plastic and extruding in to the form of pellets which then go on to manufacture the next lot of plastic products.

Quality Control & Inspection

We have a well-equipped and professional QC department, to ensure that our product are in line with the standards.

HD

LD

PET

PVC

PP